Make The Most Of the Life Expectancy of Your Equipment With Quality Bearing Bushings

In the globe of machinery, where efficiency and performance are critical, the role of bearing bushings can not be overemphasized. The quality of the bushings utilized can dramatically affect the life-span of your machinery. By the end, you will certainly have a solid understanding of how quality bearing bushings can maximize the long life of your equipment, leaving you anxious to uncover the secrets behind this crucial element.

Understanding the Duty of Bearing Bushings

Birthing bushings play an important duty in the smooth operation and durability of equipment. These significant yet small elements are developed to minimize rubbing and offer support between 2 relocating parts - bronze bushing. They work as a barrier in between the revolving shaft and the fixed real estate, permitting efficient and smooth activity

One of the primary functions of birthing bushings is to reduce rubbing. As the rotating shaft relocations, the bushing assists to minimize the quantity of resistance in between the shaft and the housing. This not only prevents extreme damage on the equipment yet additionally makes sure that the elements can move freely without any unnecessary drag.

In enhancement to reducing rubbing, bearing bushings also offer assistance and stability to the relocating parts. They assist to disperse the tons equally and avoid any imbalance or extreme motion. This is especially crucial in durable machinery or tools that operates under high lots or severe problems.

Furthermore, birthing bushings assist to soak up shock and vibrations, thus safeguarding the equipment from damages. They act as a padding, taking in any kind of effect or sudden pressures that might occur during procedure. This not only enhances the general performance of the equipment yet additionally extends its life-span.

Advantages of Making Use Of High-Quality Bearing Bushings

Utilizing high-quality bearing bushings provides countless benefits for equipment performance and durability (bronze bushing). These bushings act as a safety obstacle, reducing rubbing and protecting against deterioration on the equipment's relocating parts. By lessening rubbing, top notch bushings help to preserve the smooth procedure of the machinery, which subsequently improves its general performance

In addition, top quality bearing bushings likewise contribute to the general efficiency of the machinery. By reducing rubbing and decreasing power loss, the machinery can operate much more smoothly and with much less power usage. This not only boosts the effectiveness of the machinery yet additionally aids to lower operating expenses.

Furthermore, making use of high-grade bearing bushings can additionally minimize repair and maintenance prices. By preventing extreme damage on the equipment's moving components, the demand for constant repairs or replacements is substantially lowered. This converts to set you back financial savings for the owner or operator of the equipment.

Variables to Consider When Picking Bearing Bushings

When picking bearing bushings, it is vital to carefully think about numerous aspects that add to their overall efficiency and viability for certain equipment applications. The selection of bearing bushings can substantially affect the have a peek at this site life expectancy and efficiency of equipment, making it vital to make educated choices.

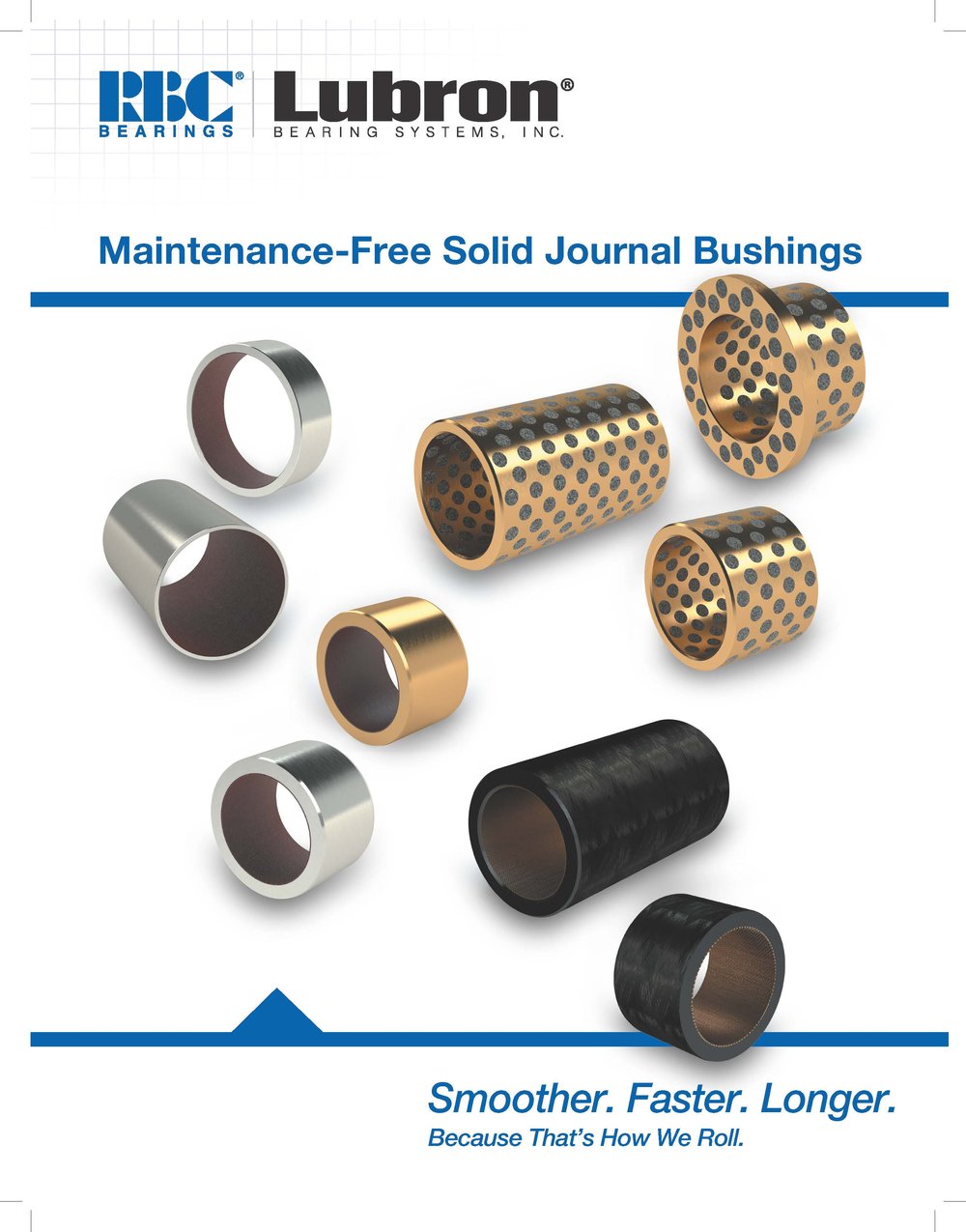

Among the main aspects to think about is the material made use of in the production of the bearing bushings. Different products have unique buildings that influence their efficiency under numerous problems. Variables such as load ability, temperature resistance, lubrication needs, and deterioration resistance need to all be considered when picking the material for the bearing bushings. Common materials used consist of bronze, steel, and self-lubricating products like PTFE or graphite.

An additional important consideration is the kind of birthing bushing required for the equipment application. Variables such as lots capability, rate, direction of motion, and alignment demands should be taken into consideration when picking the appropriate kind of bearing bushing.

Additionally, the dimension and dimensions of the bearing bushings ought to be very carefully reviewed. Appropriate sizing makes certain that the bearing can take care of the expected lots and reduces the risk of premature failing.

Correct Setup and Upkeep of Bearing Bushings

To ensure ideal efficiency and durability of bearing bushings, proper installation and regular upkeep are important. Improper installation can lead to premature wear and failure of the bushings, triggering pricey downtime and possible damage to the machinery.

Routine upkeep is equally important in making the most of the lifespan of bearing bushings. This involves regular assessments to look for any type of indications of wear or damages, such as extreme play or noise. Lubrication is also important for proper functioning of the bushings. Applying the proper lubricating substance at recommended periods aids to minimize friction and wear, preventing early failure.

Additionally, it is necessary to keep an eye on operating conditions and make any needed adjustments. Factors such as rate, tons, and temperature level can influence the efficiency of the bearing bushings. By keeping a close eye on these variables and making any essential alterations, you can make sure that the bushings are operating within their made parameters, decreasing the danger of failure.

Troubleshooting Common Issues With Bearing Bushings

Conclusion

In conclusion, utilizing top quality bearing bushings can significantly take full advantage of the life-span of equipment. Investing in high quality bearing bushings is a smart choice for extended machinery sturdiness and efficiency.

By the end, you will have a solid understanding of just how quality bearing bushings can make the most of the longevity of your machinery, leaving you anxious to find the secrets behind this necessary element.

Utilizing top notch bearing bushings uses various advantages for equipment efficiency and long life.Furthermore, premium bearing bushings also add to the general efficiency of the machinery.In final thought, utilizing premium bearing bushings can considerably optimize the lifespan of equipment. Investing in top quality bearing bushings is a smart decision for long term machinery sturdiness and effectiveness.